At STORM Building Products, we offer a full range of flat sheeting as part of our Stratus range. However, with several plastic sheeting options available to you, how do you know which is right for your application?

Here’s our guide to the different types of flat sheeting, each boasting a unique set of features and benefits, to help you decide.

Solid polycarbonate flat sheeting

Solid flat polycarbonate sheeting is a flat extruded polycarbonate sheeting with the transparency of glass and the strength of steel. It can be cold bent, fabricated and formed to suit a wide variety of applications, including commercial glazing. It’s also UV protected on both sides and has the option of being embossed. For more guidance on using polycarbonate sheeting here’s our guide on everything you need to know about polycarbonate sheeting 2018.

Uses of Solid polycarbonate flat sheeting:

Due to its durability, weight and flexibility, solid polycarbonate flat sheeting is extremely versatile, providing an alternative to glazing in:

- Conservatories

- Canopies

- Vertical glazing

- Curved and industrial rooflights

- Covered walkways

- Train windows

- Bus shelters

- Traffic lights

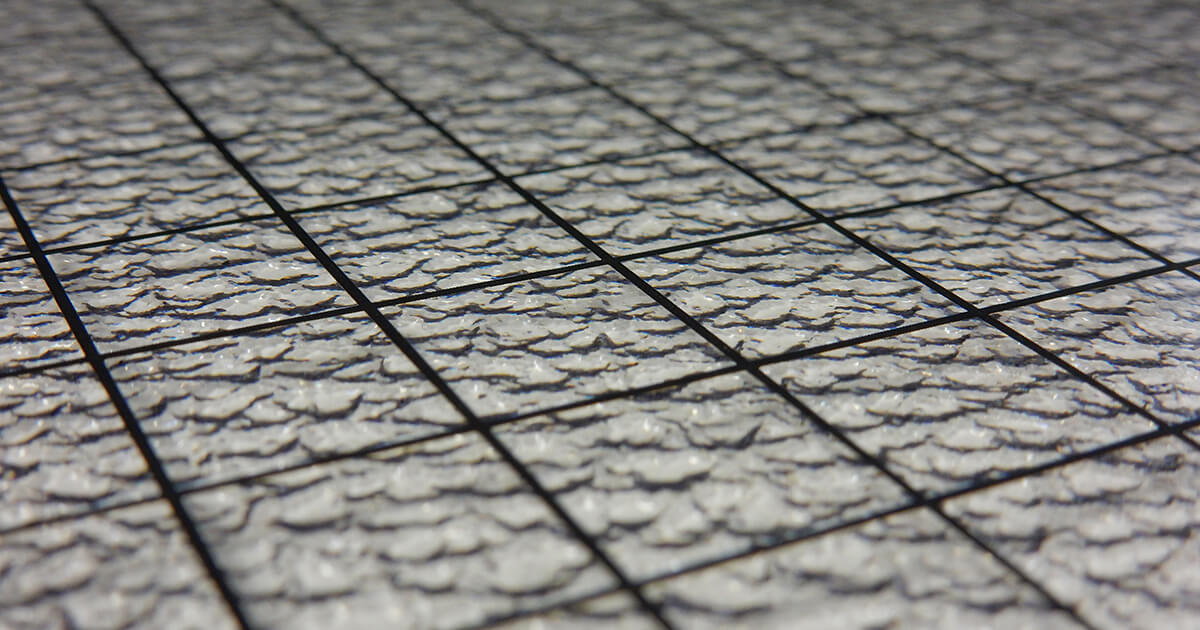

There are also types of clear flat polycarbonate sheeting specifically designed to replace potentially dangerous Georgian Wired Glass. Plasiax Wire is half the weight of glass and virtually unbreakable but still allows you to maintain the Georgian Wire image with an innovative grid etched into the sheet surface.

Uses for PlasiaxWire:

Plasiax Wire can replace traditional Georgian Wired Glass in:

- Roof glazing

- Balustrade panels

- Shop units/shelving

- Overhead safety glazing

- Heritage and listed building glazing

- Public transport

- Canopy and walkway glazing

- Door vision panels

- Partitions

- North light glazing

- Windows

- Rooflights

- Skylights

Polypropylene fluted sheeting

Another form of flat plastic sheeting is Correx, which is fluted polypropylene sheeting. Often referred to as Correx plastic, this Twinwall polypropylene sheet material comprises of two layers; two flat sheets with a ribbed centre. The result is a lightweight, cost-effective short-term signage and packaging material that’s extremely easy to handle.

Uses for Polypropylene Correx sheeting:

- Surface protection

- Packaging

- Signage

- Pet enclosures

Fluted polypropylene sheeting can be used for protecting surfaces, such as a hardwood flooring, when heavy equipment is being passed over it.

Mirrored acrylic flat sheeting

Mirrored flat acrylic sheeting is lightweight and easy to fabricate, cut and install, making it a far easier and safer alternative to glass mirror in a huge variety of applications where safety is paramount.

Mirror acrylic flat sheeting uses:

- Replacing glass mirrors anywhere

Acrylic flat sheeting can replace glass mirrors anywhere, whether in bathrooms, shops, or cars. Old, cracked glass mirrors are often unsafe and more difficult to maintain, hence mirrored acrylic has become such a popular alternative. Acrylic also has a higher impact resistance, whereas glass will crack or shatter, so it’s a fantastic option for schools, stables, mental institutions, and prisons.

Recycled plastic flat sheeting

Storm Board is recycled plastic flat sheeting that’s ideal for site hoarding due to its weatherability, impact strength, and ability to be vinyl wrapped. It’s made using waste plastics and is recyclable, making it the more eco-friendly alternative to plywood.

Recycled plastic flat sheeting uses:

- Site hoardings

- Concrete formwork/shuttering

- Furniture

Storm Board is great for temporary applications as it can be reused and recycled, unlike plywood. It’s particularly popular for site hoardings as it can withstand harsh weather conditions and can be made to a specific colour, printed or vinyl wrapped for use as a marketing tool on site. It can also replace plywood in concrete formwork/shuttering, giving you a reusable and more durable solution.

Companies can even have their own back of house plastic taken away to be formed into this recycled flat sheeting, which can then be used to make indoor or outdoor furniture, turning waste into something useful for their staff and customers.

Tips for handling & installing flat sheeting

Plastic flat sheeting can be vulnerable to scratching, so make sure you take this into consideration when storing and handling. It’s best to always keep a protective film on the sheets until the job is complete.

When purchasing your flat sheeting always try to order cut to size to save cutting on-site. However, if you do need to cut your sheeting use a fine tooth saw at a slow speed. For drilling flat sheeting, use a HSS drill bit.

When fixing mechanically, always ensure the hole is larger than the fixing screw to allow for expansion. If you’re fixing with adhesive instead, be sure the adhesive is compatible with the product.

The best way to clean flat sheeting is to only wash with warm, soapy water and use a non-abrasive cloth.

Where to buy flat sheeting

Here at STORM Building Products, we supply plastic flat sheeting in a range of thicknesses and sizes. Get in touch today to find your nearest distributor!

This article was written by Jade Mitchell.

Jade is the Marketing Coordinator at STORM Building Products, she has been working in the building plastics industry since 2016 and has completed ISMM level 2 and 3.