What is Twinwall and Multiwall polycarbonate sheeting? Polycarbonate sheeting presents itself as a leading material due to its durable and rigid structure. Typically polycarbonate sheeting is formed into a sheet by an extrusion process. Its impact resistance is 250 times that of glass and surpasses many other plastic materials such as acrylic. Essentially, it’s virtually unbreakable.

Our Polycarbonate sheeting comes in different styles, most notably Twinwall and Multiwall. The choice to choose polycarbonate sheeting for your next project might be simple but understanding which type you need might not be. In this article we’ve covered the following:

- What is Twinwall sheeting?

- What is Multiwall sheeting?

- Twinwall vs Multiwall

- Which is best?

- Where to buy polycarbonate sheeting in UK

What is Twinwall polycarbonate sheeting?

Twinwall sheeting refers to two exterior pieces of polycarbonate connected by an interior plastic support that allows the two plastic sheets to run parallel to one another. This method of layering increasingly enhances its strength and ability to support weight, furthering its favourability as a material for projects.

At STORM all of our Twinwall Polycarbonate is characterised by high optical clarity, light transmission, impact resistance and durability. We provide all of our Twinwall sheeting in a vast range of sizes with varying depths:

4mm Twinwall Polycarbonate Sheeting

- Has a coextruded UV protection layer on one side. This is under the branded film and must be installed facing outside.

- Light transmission: 85%

- Maximum Width: 2100mm

- Nominal Sheet Weight: 0.8 kg/m²

- U-value: 3.9 W/m²°K

- Mini Curve Radius: 600mm

6mm Twinwall Polycarbonate Sheeting

- Has a coextruded UV protection layer on one side. This is under the branded film and must be installed facing outside.

- Light transmission: 82%

- Maximum Width: 2100mm

- Nominal Sheet Weight: 1.2 kg/m²

- U-value: 33.7 W/m²°K

- Mini Curve Radius: 900mm

10mm Twinwall Polycarbonate Sheeting

- Has a coextruded UV protection layer on one side. This is under the branded film and must be installed facing outside.

- Light transmission: 82% (Clear), 33% (Bronze), 40% (Opal)

- Maximum Width: 2100mm

- Nominal Sheet Weight: : 1.5 kg/m²

- U-value: 3.2 W/m²°K

- Mini Curve Radius: 1500mm

What is Multiwall polycarbonate sheeting?

Multiwall Polycarbonate is the most prevalent form of polycarbonate sheeting, often used for conservatories and lean-to roofs. The various layers it’s composed from provide superb thermal insulation and relatively good sound insulation.

16mm Multiwall Polycarbonate Sheeting

- Has a coextruded UV protection layer on one side. This is under the branded film and must be installed facing outside.

- Light transmission: 85% (Clear), 18% (Bronze), 42% (Opal)

- Maximum Width: 2100mm

- Nominal Sheet Weight: 2.5 kg/m²

- U-value: 2.4 W/m²°K

- Mini Curve Radius: 2400mm

25mm Multiwall Polycarbonate Sheeting

- Has a coextruded UV protection layer on one side. This is under the branded film and must be installed facing outside.

- Light transmission: 62% (Clear), 11% (Bronze), 28% (Opal)

- Maximum Width: 2100mm

- Nominal Sheet Weight: 3.1 kg/m²

- U-value: 1.4 W/m²°K

- Mini Curve Radius: 2400mm

- Not recommended for curved applications

32mm Multiwall Polycarbonate Sheeting

- Has a coextruded UV protection layer on one side. This is under the branded film and must be installed facing outside.

- Light transmission: 64% (Clear), 7% (Bronze), 33% (Opal), 7% (Bronze/Opal), 4% (Solarguard)

- Maximum Width: 2100mm

- Nominal Sheet Weight: 3.6 kg/m²

- U-value: 1.25 W/m²°K

- Not recommended for curved applications

35mm Multiwall Polycarbonate Sheeting

- Has a coextruded UV protection layer on one side. This is under the branded film and must be installed facing outside.

- Light transmission: 63% (Clear), 7% (Bronze), 33% (Opal), 7% (Bronze/Opal), 4% (Solarguard)

- Maximum Width: 2100mm

- Nominal Sheet Weight: 3.9 kg/m²

- U-value: 1.2 W/m²°K

- Not recommended for curved applications

Twinwall vs Multiwall: when to use it?

Generally, Twinwall and Multiwall polycarbonate have the same properties but they offer different levels of insulation. The easiest way to remember this concept is that the more layers a sheet has, thereby more thickness, the more insulation is provided. If a structure requires heat containment or is a place of residence then Multiwall is going to be the more suitable choice as it provides more insulation.

Traditionally, 4mm and 6mm Twinwall are suitable enough for greenhouses, cold frames and sheds. They are easy to manoeuvre and adhere to even fairly unusual fits due to their lightweight structure and curving capacity.

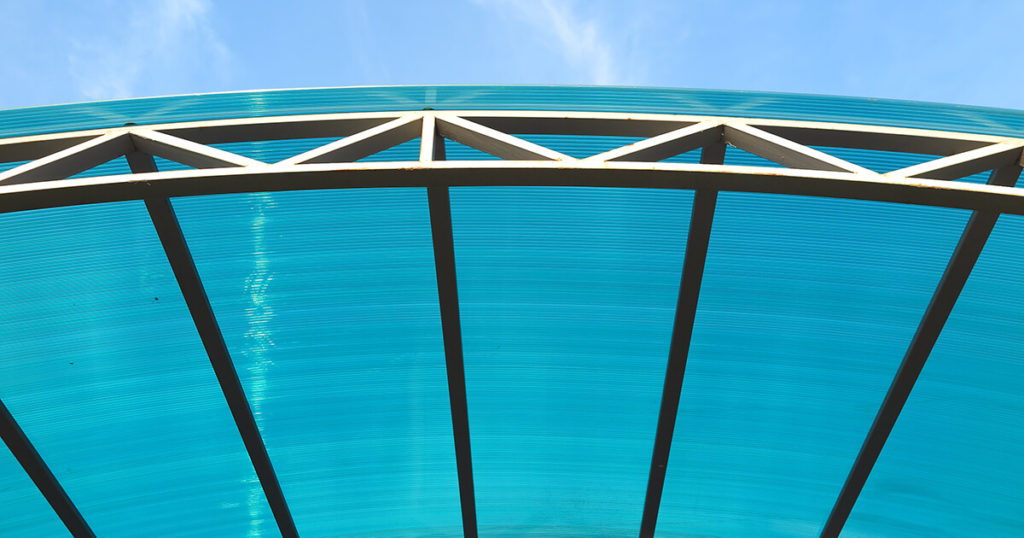

10mm polycarbonate sheeting is appropriate for carports, pergolas and sheds as well. Although a thinner polycarbonate can be used for sheds, it is completely down to the user about how much insulation they require or how strong they believe their structure needs to be, or how rigid.

The thicker polycarbonate sheets such as 25mm, 32mm and 35mm Multiwall sheeting are going to provide the highest level of insulation and are therefore more than adequate to be used as the roof of a conservatory. Its translucent quality enables light to filter through, allowing bright and ambient spaces to be created that maintain their warmth throughout the year.

Other uses for polycarbonate sheeting include, but are not limited to:

- Vertical glazing

- Sporting goods

- Bus shelters

Which polycarbonate roofing sheets are best?

Coming to a decision about the best choice between Twinwall and Multiwall is always going to depend on the requirements of your project as well as the time, methods and cost you have to install it.

For example, if a customer wishes for a room with more light then a polycarbonate sheet with a higher level of light transmission is going to be the more favourable and appropriate option e.g. a greenhouse.

We’re always happy to answer any questions you might have about the best products for your upcoming projects.

Where to buy polycarbonate sheeting in the UK?

Our range of polycarbonate sheeting is a cut above the rest. With a large range to choose from including diverse shades and sizes, we can cater for any requirements your next project might present.

By using our easy ordering process and prompt delivery service, you can be on your way to finishing off a conservatory or popping up a greenhouse for summer crops in no time. Find your local distributor for STORM products today or consider turning your business into one!

Nothing is too much trouble for us here at STORM, so don’t hesitate to contact us with your business enquiries or project details.

This article was written by Jade Mitchell.

Jade is the Marketing Coordinator at STORM Building Products, she has been working in the building plastics industry since 2016 and has completed ISMM level 2 and 3.